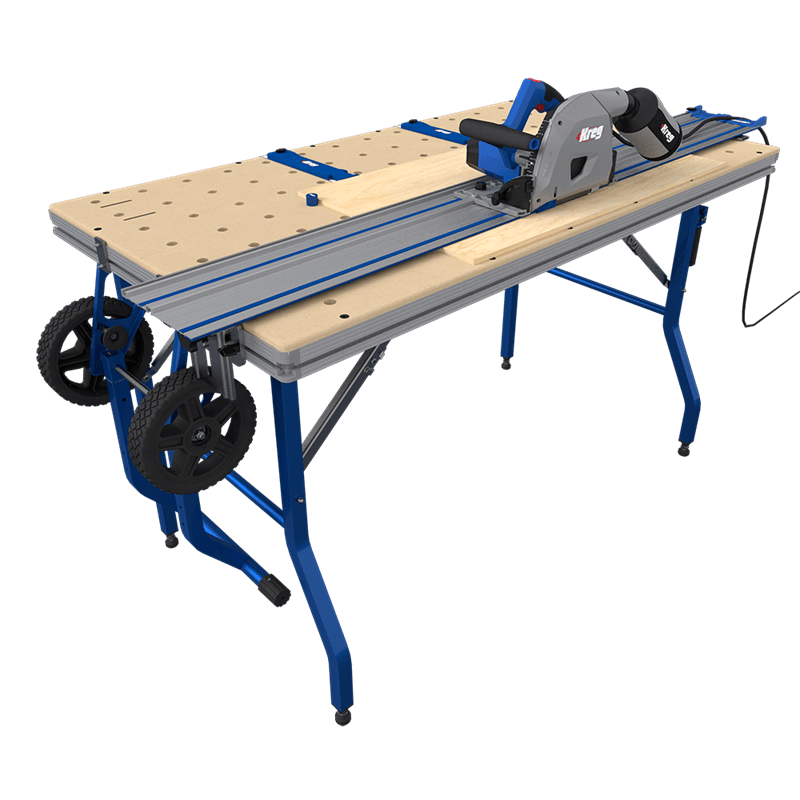

Kreg’s Adaptive Cutting System (ACS) features a track saw, folding project table and guides—all in one cohesive system. It’s highly portable, easy to store and capable of delivering repeatable, accurate cuts. It’s also loaded with safety features. This system is ideal for woodworkers who have limited room in their shops or anyone who uses their workspace for other purposes like, say, parking a car.

Shop the Kreg Adaptive Cutting System now or continue reading to learn more about the components that make up the system.

Kreg Adaptive Cutting System

For a while now, track saws have made it possible for woodworkers to accurately break down large panels and sheet goods without using a table saw and extensions. The Kreg ACS takes the next step, adding a folding project table that works in concert with Kreg’s plunge saw, guide track and system of guides and stops. The project table helps you position, secure and support workpieces, while the plunge saw and guide track facilitate precise, splinter-free results for a variety of cuts: rips, crosscuts, angles, bevels, mitres and more.

Precise Cutting

Cutting dimensional sheet goods and large panels—plywood, MDF, hardwood panels, for example—can be tricky, even with a cabinet saw. The Kreg ACS allows you to crosscut solid wood, rip your own dimensional lumber, break down plywood and make precise angle cuts.

Using the repetitive stops included with the project table, you can turn your garage into a highly efficient production workshop, and make repeatable cuts consistently and accurately—dead on square every time. For example if you’re cutting rails and stiles, you can position the stops at the required length for each piece and cut both on a single pass.

Thanks to the layout of the table’s precision-machined holes and Kreg’s Versa-Stops, making 45 and 90 degree cuts is simple. In addition, the ACS mitre gauge sets up angle cuts from 0 to 60 degrees.

Because the system is accurate and stable, you can put it to work cutting boards of all shapes and sizes:

- Cut your own dimensional lumber—as narrow as 1″—from hardwood panels or plywood.

- Rip large boards into the widths you need for each project.

- Trim and square inexpensive construction lumber to eliminate rounded edges.

- Break down sheet goods using just the plunge saw and guide track, or the entire system.

Kreg ACS Plunge Saw: Loaded with Safety Features

The Kreg ACS plunge saw is equipped with a 12 amp motor, electronic brake and a full blade shroud. The blade itself is 6-1/2″ in diameter with 48 carbide-tipped teeth. It’s made to rip and crosscut a range of materials including hardwood.

The saw’s handles are positioned to keep your hands as far from the blade as possible. What’s more, the saw features a left-mounted blade. This makes it easy for right-handed users to control the saw and see the blade while cutting.

Additional safety features on the saw include the following:

- Retractable riving knife prevents the blade from binding.

- Selectable anti-kickback system keeps the saw from moving backwards

Stable Platform + Handy Guides = Clean, Accurate Cuts

Like most other track saw systems, the Kreg ACS track has a flexible anti-splinter strip along the blade-side edge to prevent chipping and tear out. There’s also an anti-splinter feature on the saw itself to prevent chipping on the non-track side.

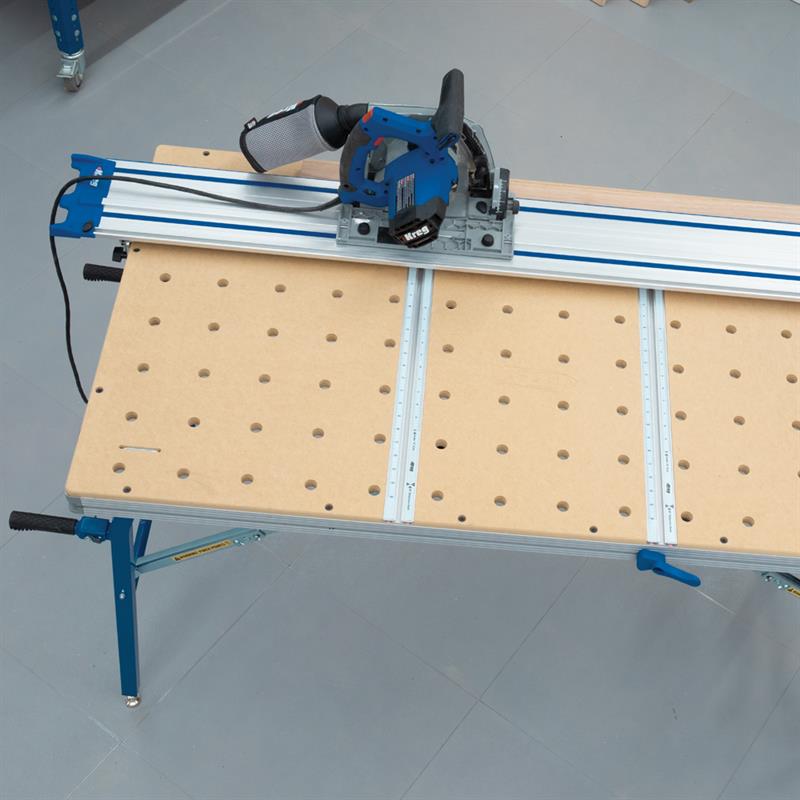

Where the Kreg system differs from other track saws is how the guide track connects to the project table. The track fastens to a hinge and mounting plate at each end. Once mounted, the track can be raised and lowered to accommodate workpieces of various thicknesses and lengths. So instead of moving the track out of the way after each cut, you simply raise it up, position the next workpiece, lower the track and start cutting.

Another cool feature on the track is the end cap. It keeps the cord and dust extractor hose out of the way while you cut.

Integrated Guides

The project table’s integrated guide system includes an onboard rule for measuring cuts from 1″ to 48″ long or wide, as well as rules on both T-tracks. This allows you to quickly and accurately set the repetitive stops in position.

The project table includes a mitre guide, four Versa-Stops, two repetitive stops and more.

Optional parallel guides provide accurate off-table cutting. These guides lock onto the track and can adjust from 13″ to 96″.

To extend cutting capacity to 124″, purchase a second guide track and a pair of ACS track connectors. Other options include extension brackets that expand the table to accommodate larger workpieces.

Mobile and Easy to Store

One of the Adaptive Cutting System’s major upsides is its portability: Because the ACS project table sets up and folds away quickly, it’s well suited for anyone with a smaller work area.

Moving and storing the ACS is also simple: It has folding handles that make it easy to control, and 8″ wheels with grippy tread that maneuver over concrete, gravel, grass and dirt. For storage, the ACS project table stands vertically with a relatively small footprint, so you can wheel it to the side of your garage before backing in the minivan.

Learn More

The Kreg Adaptive Cutting System is versatile and portable, and is capable of delivering high-quality results on a variety of projects. For woodworkers looking to make the most of a limited work area, this system is a space-saving solution that comes with features that will save time and deliver consistent and precise results. To learn more about the ACS, visit your nearest KMS Tools location or stop by kmstools.com.